ros. Espectrometro de emision op tica, Analizador de carbono |hidrogeno | azufre. Gap & flush, sistemas de medicion, di

tica, Analizador de carbono |hidrogeno | azufre. Gap & flush, sistemas de medicion, di

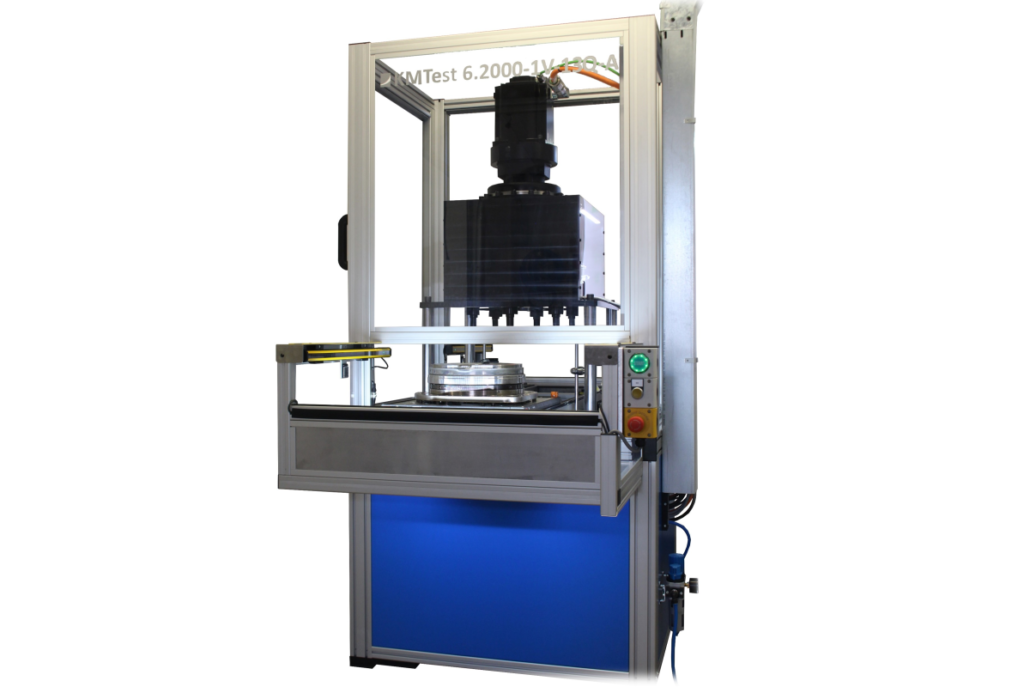

Horizontal Torsion Rotatory Testing Machines

Electromechanical horizontal rotary torque – torsion testing machines of the KM.4 series in table or stand design up to 5000Nm, which are primarily intended for measuring torque at different or constant speeds of both samples, parts and whole products. These machines are suitable for research and development, routine quality control in laboratories and operations, but also for assembly and testing semi-automatic lines. LABORTECH machines are characterized by very high rigidity of the test frame, speed and accuracy of measurement in semi-automatic mode.

KEY FEATURES OF THE KM.4 SERIRES

- Robust horizontal stand modular design with mechanical resistance and durability.

- Abnormally high rigidity and mechanical resistance of the machine combined with ergonomics at a high level.

- Integrated torsion mechanism on the left side of the machine. Dynamic AC servo drive with continuous speed control via converter or servo converter.

- The KM series machine comply with all the above-mentioned EC directives on machinery and equipment and work in accordance with the new safety functions according to EN ISO 13850:2015

- The basic control of the machine is performed by SIEMENS PLC with integrated touch LCD display with FAROTest software in the base of the machine or higher FULL version with measuring and control electronics of the EDCi series with a sampling frequency of 2.5 or 10 kHz. Analog signal resolution level ± 250,000 divisions (20 ms).

- Complete evaluation and test control software for testing materials in torsion – KMTest – BASIC – module R or as an extension of the FAROTest software.

- Protective safety covers made of ITEM profiles and polycarbonate with high safety EN ISO 13849-1 /2 or safety barrier.

- Possibility to control and set up the machine using a touch LCD monitor. Wide range of accessories – test mandrels, fixtures, chucks, etc.

tica, Analizador de carbono |hidrogeno | azufre. Gap & flush, sistemas de medicion, di

tica, Analizador de carbono |hidrogeno | azufre. Gap & flush, sistemas de medicion, di

tica, Analizador de carbono |hidrogeno | azufre. Gap & flush, sistemas de medicion, di

tica, Analizador de carbono |hidrogeno | azufre. Gap & flush, sistemas de medicion, di tica, Analizador de carbono |hidrogeno | azufre. Gap & flush, sistemas de medicion, di

tica, Analizador de carbono |hidrogeno | azufre. Gap & flush, sistemas de medicion, di tica, Analizador de carbono |hidrogeno | azufre. Gap & flush, sistemas de medicion, di

tica, Analizador de carbono |hidrogeno | azufre. Gap & flush, sistemas de medicion, di