ros. Espectrometro de emision op tica, Analizador de carbono |hidrogeno | azufre. Gap & flush, sistemas de medicion, di

tica, Analizador de carbono |hidrogeno | azufre. Gap & flush, sistemas de medicion, di

tica, Analizador de carbono |hidrogeno | azufre. Gap & flush, sistemas de medicion, di

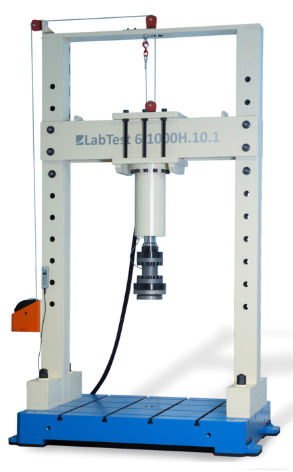

tica, Analizador de carbono |hidrogeno | azufre. Gap & flush, sistemas de medicion, diH.10 – DYNAMIC AND STATIC TEST BENCHES

The dynamic hydraulic test benches of the H.10 series are designed for forces up to 10MN and use a platform of T-grooved plates or load-bearing structures. They are designed to perform low and high cycle fatigue tests of parts or entire products. This range of machines is characterized by high frame rigidity and mechanical resistance. The range of a given machine depends on the dynamic stroke, test force, frequency and sample size. A specific test set is derived from these parameters, which consists of a test frame – T-slot plate, a combined servo-hydraulic cylinder and a hydraulic unit.

General key features of the H.10 series

- Robust horizontal or vertical stand or table design with integrated hydraulic cylinders or electric actuators.

-

- The assemblies consist of T-slot plates of different dimensions and for different loads or directly T-slot profiles built into the concrete floors in the test halls.

-

- 3D simulation is a matter of course when developing these products.

-

- Each servo-hydraulic test set of the H.10 series includes compact hydraulic units of the HAD or HAS series operating with a maximum constant pressure of 210, 280 or 350 bar.

-

- Monitoring of all Hydrauli units states is performed by the HALT 18 unit with PLC Simatic and LCD display.

-

- The Hyudraulic unit design is always carried out according to the customer’s requirements and depends on the F max and the number of test axes.

-

- The Load cells on each actuator operate in the accuracy class according to EN ISO 7500-1, ASTM E4.

-

- The machine is controlled by measuring and control electronics of the EDCi series with a sampling frequency of 2.5 or 10 kHz. Analog signal resolution level ± 250,000 divisions (20 ms).

-

- Possibility to control and set the machine using a touch LCD monitor and RMCi controller.

-

- Complete evaluation and control of the axial or combined torsion test is provided by the Test & Motion material testing software – Test&Motion – DYNPACK.

-

- Wide range of accessories – test pins, jigs, fixtures, etc.