ros. Espectrometro de emision op tica, Analizador de carbono |hidrogeno | azufre. Gap & flush, sistemas de medicion, di

tica, Analizador de carbono |hidrogeno | azufre. Gap & flush, sistemas de medicion, di

tica, Analizador de carbono |hidrogeno | azufre. Gap & flush, sistemas de medicion, di

tica, Analizador de carbono |hidrogeno | azufre. Gap & flush, sistemas de medicion, diEASYFLAG 3000,BRINELL HARDNESS TESTER FOR FORGES, CASTINGS AND HEAT TREATMENTS

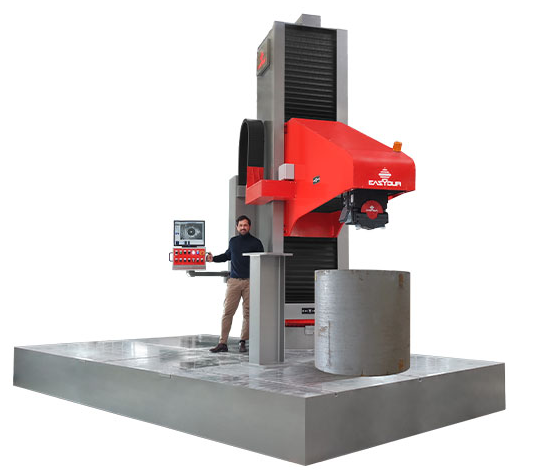

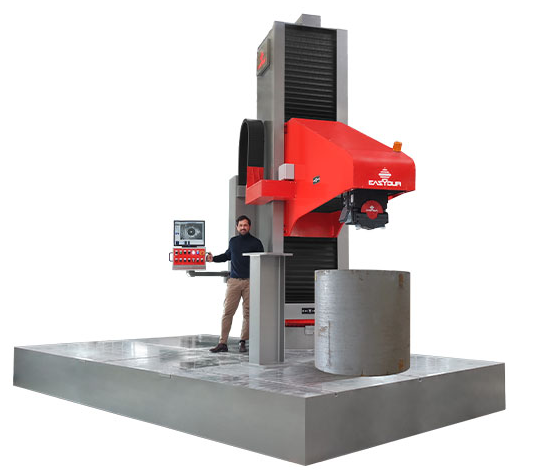

Easyflag 3000 is a special Brinell hardness tester with integrated milling system, developed for solving the typical issues of radial drill hardness testers, unable to properly bear loads higher than 3000 kg (Brinell 10/3000 hardness test + the force needed to hold the piece) nor the vibrations induced by the surface preparation process. Its special configuration, along with the self-learning functionalities, allow to perform series of hardness tests on components of different sizes: whether you need to test big forgings, or smaller castings or even heat treated parts, Easyflag 3000 is the hardness testing solution for you. These features make this special hardness testers the go-to choice for those forges and metallurgy companies which need to improve their hardness testing routine, transforming it into a true production process.

Easyflag 3000 is an industrial hardness testing machine which, as the name suggests, has a “flag” configuration, making it a radial hardness tester. It is extremely sturdy and reliable, characteristics which make it the ideal hardness tester for forges, foundries, heat treatments and metallurgy in general.

Therefore, Easyflag 3000 series is suitable for Brinell hardness tests on medium as well as large and heavy components, such as casts and forged parts.

In fact, it finds numerous uses thanks to its versatility, deriving from the possibility to rotate through 180° (or, if needed, even 360° with the insertion of additional pallets).

This casts and forgings hardness tester is available in 2 versions, according to the productivity needs: one fully automatic (Big Easyflag) with larger dimensions and a smaller one, with manual axes (Mini Easyflag), respectively with hardness testing surfaces of 5.500×3.250 mm and 2.650×2.000 mm.