Shop Floor and Special Application Coordinate Measuring Machines <---

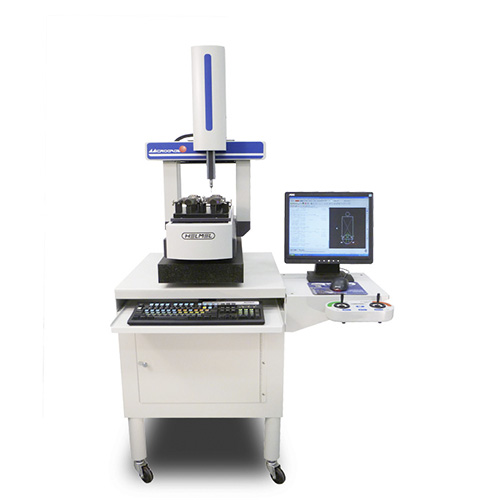

Microgage - Coordinate Measuring Machine

Finally, the highest CMM accuracies are available to everyone

Microgage Advantage.

Until Microgage, the cost of this level of 3D precision has been 3 to 10 times higher, and the choices have been limited to much larger machines. The need for the highest precision is often found in the smallest parts, yet there has been no choice but to buy a relatively huge CMM for these tasks, wasting money and valuable floor space.

The right Mini CMM at the right time.

Microgage is modeled on the World’s most precise machine tools, having a rigid fixed bridge design made of steel. And like machine tools, the mechanical bearings and guide ways, along with motors and scales, are covered and protected for durability, stability, and life-long value. Bearings are classified within 120 nanometers in X and Y, and the entire structure is stress-relieved and thermally shielded inside and out, as well as vibration dampened.

Accuracy is intrinsic: there is no software error correction, just pure physical precision. If high precision in small and medium sized parts is your game, Microgage is the answer made simple, whether in the lab or for production.

In a world going micro, the Microgage tabletop CMM has arrived!

Scanning solution in a small package.

The Microgage can be configured for scanning operations by adding the options;

-

Renishaw SP25M scanning system.

-

PM1 Helmel specific Probe Head adapter.

-

UCC2 universal CMM controller.