High Accuracy Measurement Systems <---

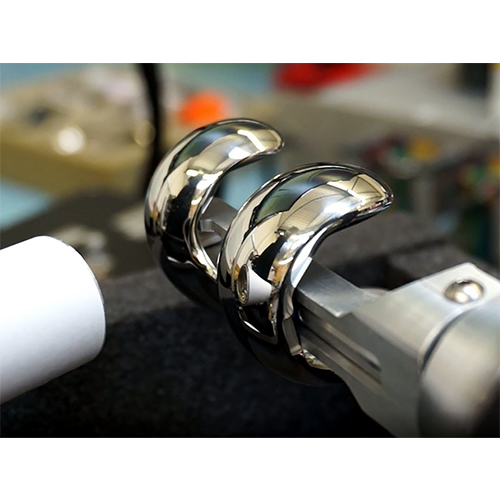

OrthoLux - Inspection of Artificial Joints

The OrthoLux is a non-contact optical coordinate measuring machine that measures the component form of artificial joints in a variety of materials with applications in Production and R&D. The validated methodology uses optical profiling to generate 3D data sets with resolutions as low as 20 nanometres. The use of optical sensors contributes to extremely high measurement speed and ensures that the delicate bearing surfaces are not damaged.

Technical Details:

-

True 3D measurement with PASS/FAIL measurement report or fully illustrated residual error maps.

-

Example customisable output parameters include: Radius of bearing surface of hip head and cup, edge geometry of cup, head and stem taper angle and straightness, comparison to CAD, local radius of curvature.

-

Various models at different accuracy and speed levels to suit your requirements.

| |