Video Measurement Systems <---

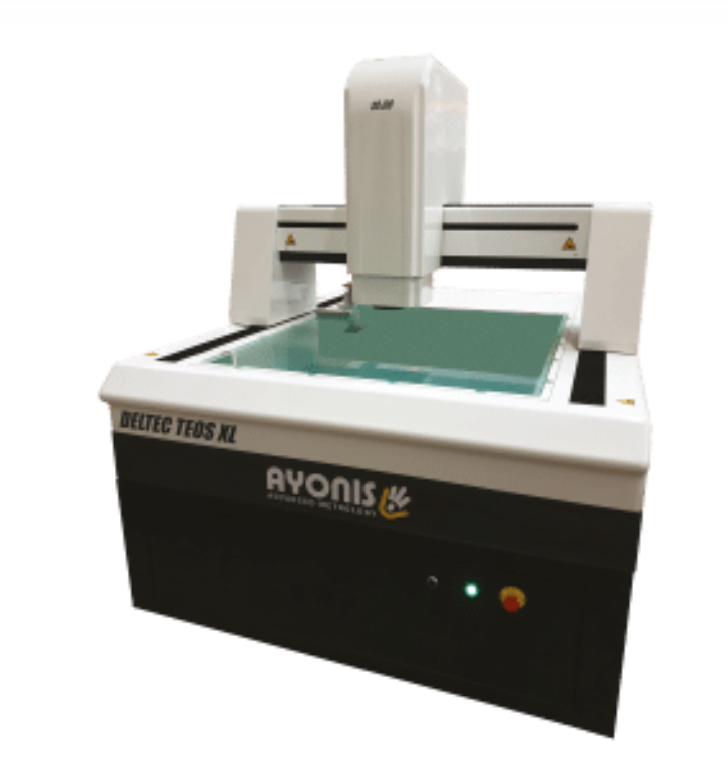

DELTEC TEOS XL

This machine brings together all the tools for your dimensional metrology(software suite and 3D structure).

Compatible with all types of parts (automotive, mechanical, electronic,pharmaceutical, and so on) and materials (metallic, plastic, rubber, glass,and so on).

Suitable for all controls: first part, process, laboratory, at entrance, at exit,during production...

Ability to manage multiple sensors: vision, probe (Renishaw®), confocal.

Programming by self-learning.

Automatic control of parts (single or multiple).

PHOTOS Granite structureConfocal sensorMulti-sensor headStylus chargerDual screen workstationDELTEC TEOS XL3D automatied measuring system multisensor.

Machine features:

• Structure with mobile gantry

• Base and gantry in solid granite

• Line ar roller guides

• Ball screws and DC motors

• Measuring capacities (X, Y, Z) :

o 600 x 80 0 x 200

o 800 x 10 00 x 200

o 1200 x 10 00 x 200

• Loa d cap acity : 20 kg

• Encoders resolution: 0.5 μm • X, Y, Z speed: 200 m m/s ma xi mum

Uncertainties of measurement (2σ):

• XY E2: (±4.0+5L/1000) μm (vision, probe)

• Z E1: (±4+5L/1000) μm (vision)

• Z E1: (±2.4+5L/1000) μm (probe)

Vision:

• Highdefinition1.3 MPXB&W digitalcamera

• Programmablelighting devices:

o Episcopicwhite LED8 sectorso Coaxial LED

o Diascopic collimated green LED

• Motorizedzoom with 6indexed positions

• Magnifications x30 to x200 (as an indication in full field display on 24’’ screen)

• Positioningeasedthanksto laser pointing